Cork suppliers step toward TCA-free future

Natural cork producers are ramping up their efforts to stay ahead of alternative closure suppliers with the development of new technology that promises to eliminate TCA cork taint.

While the percentage of natural cork closures affected by TCA has declined dramatically in the past decade, it continues to impact a very small percentage of global cork production. Presently, most natural cork suppliers carry out sensory testing on corks which involves a human nose testing individual corks for traces of TCA. This is not only time consuming and expensive, but invites the possibility for human error.

Now, cork producers are taking the next steps to becoming entirely TCA-free, using technology that claims to offer a 100% success rate in detecting and eradicating TCA. Both MaSilva Portugal and Cork Supply have invested in machines that check each individual cork for traces of TCA using cutting edge gas spectroscopy technology.

Moving toward a TCA-free future

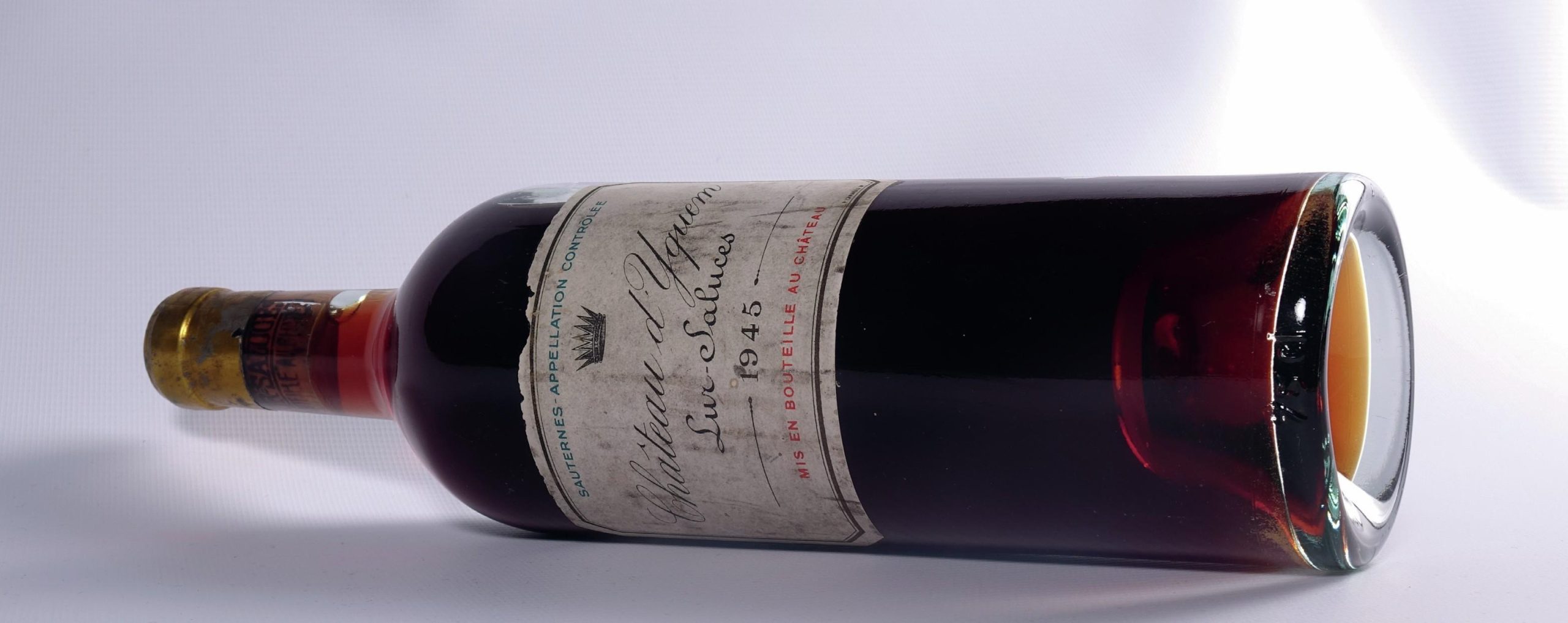

MASILVA Portugal launched its One by One service for ultra-premium wines in January, offering suppliers the assurance of 100% TCA-free corks.

Each cork is individually tested for TCA to “un-detectable” levels of 0.5ng/l, eliminating bad corks from the supply chain using gas spectroscopy. The technology was launched earlier this year after three years of research.

Speaking to the drinks business at the London Wine Fair yesterday, Miguel Cardozo, MASILVA’s global business director, described the technology as “revolutionary”, and vital in its efforts to level the playing field with alternative closures that have entered the market in the past decade.

“For many years we had a lot of competitors saying ‘we don’t have TCA like the cork guys’,” said Cardozo. “This is the first step to correcting this marketing by our competitors, which was a reality. Now we test every single cork with this solution. There are other suppliers that individually test for TCA, but this is based on people doing sensory tests. With this technology have eliminated the human error”.

Cork Supply has also upped its technological capabilities and will launch its DS100+ “dry soak” detection system for TCA in natural cork in July after three years of research. With this system, Cork Supply says it is able to guarantee 100% TCA-free corks.

“DS100+ is the result of our sustained efforts to offer our customers the very best in quality assurance,” said Cork Supply founder Jochen Michalski. “This new process will eliminate the risk of TCA in natural cork at levels as low as 1 part per trillion, a level far below sensory threshold – all at higher production volume and lower cost, providing customers with the finest quality cork at an unprecedented value.”

DS100+ will be fully operational by July 2016 and will initially be aimed at high-end wines. Cork Supply expects to examine more than 20 million corks in its first year and plans to eventually offer the service at all wine quality levels, as production costs are reduced, tripling its capacity to 60 million corks tested by 2017.

“Natural cork is growing and synthetic corks are reducing”

Partner Content

Competition in the closures category has been increasing in recent years, with synthetic and glass corks gaining ground. However Cardozo is confident that there will always be a place for natural cork.

“There has been a pressure in the last decade, yes,” admits Cardozo. “When a product is young there’s going to be exponential growth. At some point the market understands if it is a good product and it stabilises or grows. Screw cap took a share of the market and it works well for a certain style. We believe the future for plastic corks will be very challenging. The market for plastic stoppers has decreased in the last 10 years.”

Micro agglomerated corks, which are moulded from natural cork granules, are the biggest threat to natural cork producers, according to Cardozo.

“[Micro agglomerated] stoppers are the newest trend and it works well for wines that require no evolution, or for fast consumption,” said Cardozo. “But when these producers start upgrading the quality of the wines we believe there will be some issues with the wine ageing and with the wine itself, because these stoppers are not made to age wines. The structure and aromas will be different”.

“The closures market is stablising”

Michalski agrees that while cork may have more competitors to fend off, with suppliers offered more choice that event, the market for natural cork is still growing. Dismissing the threat of synthetic corks, he believes the closures market is now “stablising”.

“In the 90s when cork taint was more prevalent the synthetic corks came in and they have been growing,” explained Michalski. “Now the volumes are reducing somewhat and natural cork is actually growing. We can see this in the cork export figures. Screwcaps are growing and work well in countries like New Zealand, South Africa and Australia, but it is not growing as fast as it was a few years ago.

“It seems like the closures market is stablising compared to 10 to 15 years ago when you didn’t know which direction it was going in. I think people have played around and tried to experiment, but today I feel a lot more comfortable about where this industry is going. Natural cork is growing and synthetic corks are reducing.”

I love drinks business

How can you have a TCA concentration of 0.5 ng/L in a cork? A litre of cork, or maybe 0.5 ng per cork. or 0.5 ng/L of ‘Releasable TCA’.

Cork will always be a flawed closure. Even if TCA-less, premature oxidation, far more common than TCA, will remain a problem unsolved.

The premature oxidation problem has been solved. It has nothing to do with the physical or chemical properties of cork. It is caused by the incorporation of variable amounts of air and/or oxidants at the time of bottling and inadequate levels of sulfur dioxide.

Big step forward will happen when Cork industry won’t need to kill cork to get rid of TCA, and will separate contaminated cork bark at manufacturing

stage, not when corks are finished. Who is going to use the bad corks? Separate roten apples from good apples before they are squeezed into juice and only take aspirins if you have headaches.

Electronic releasable TCA on the Cork surface? Cork cells are only air tight only untill it is squeezed from 24 to 15mm. They will then explode and no more controls are possible. Are you serious? Shouldn’t wine people cross check this?

Premature oxidation is not caused by cork, but by the erratic incorporation of air and oxidants at the time of bottling. See ‘The random oxidation myth’, Australian & New Zealand Grapegrower & Winemaker, May, 2010.

It is my opinion that TCA in corks and a range of other food products, packaging, wooden pallets, timber flooring and dwellings and shipping containers is largely an environmental problem caused by the profligate use of chloro-phenols as biocides dating from around the 1960s